DoT Cargo Tank Testing

Reliable services for Dot Cargo Test Tank inspection

White Tank’s DoT Cargo Test Tanks

Whatever you plan on transporting, all cargo tanks are required to be inspected and tested before they are filled. Ensure yours is ready with White Tank’s reliable inspection and testing services.

Our mechanics and inspectors work hard to keep you compliant with the federal standards set by the DoT. That means we perform all the necessary assessments, including pressure testing, external visual inspection and testing, lining inspection, leakage testing, and thickness testing. We have the experience to perform these examinations on many make or model. If we find that your tank doesn’t measure up to expectations, there’s no need to worry. Our team can step in to repair it. We can then retest it to ensure it’s safe and ready for use.

Department of Transportation Testing and Inspection Requirements?

Since your cargo tank is expected to hold hazardous materials, it needs to be able to store those materials safely and securely. That’s why the DoT requires your tank to undergo several inspections and tests. These procedures include:

- External Visual Inspection (V) – Annual Test

- Leakage Test (K) – Annual Inspection

- Internal Visual Inspection (I) – Five-Year Test

- Pressure Test (P) – Five-Year Test

- Thickness Test (T) – Two-Year Test

- Upper Coupler Inspection (UC) – Five-Year Test

White Tank’s Annual and 5-Year Inspections and Testing

At White Tank & Truck Repair, we understand the critical role that cargo tank inspections play in maintaining their integrity and operational condition. With our comprehensive range of services, we can help you meet the Pipeline and Hazardous Materials Safety Administration (PHMSA) specifications, ensuring compliance and peace of mind.

Meeting PHMSA Specifications

To adhere to the regulations set by PHMSA, White Tank & Truck Repair performs a suite of yearly cargo tank inspections and tests. We specialize in conducting the necessary examinations to ensure you meet the required standards. Our qualified technicians are well-versed in the relevant PHMSA regulations, including sections 180.407(d) and 180.407(h).

External Vision Inspection (V)

As part of the yearly inspection process, our team conducts an external visual inspection (V) in accordance with section 180.407(d). This involves thoroughly examining the external condition of your cargo tank. By checking for signs of damage, corrosion, or any other potential issues, we can identify and address them promptly. This visual inspection helps ensure that your tank remains in optimal condition for safe transportation.

Leakage Test (K)

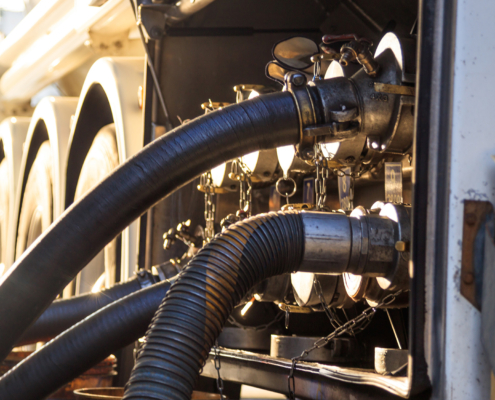

White Tank & Truck Repair also offers leakage tests (K) following section 180.407(h) of the PHMSA regulations. They identify any emissions in the tank’s package and piping system, ensuring the containment of hazardous materials during transportation. Our technicians employ advanced techniques and equipment to conduct accurate and reliable tests, ensuring that your cargo tank meets the required safety standards.

5-year Certification Requirements

We understand the importance of meeting five-year certification requirements for cargo tanks. They are crucial in maintaining structural integrity and operational condition. At White Tank & Truck Repair, we offer a range of five-year tests tailored to your specific requirements. Our team can perform the necessary examinations, including internal inspections, pressure tests, and other assessments, to ensure your tank remains compliant and fully functional.

Are you looking for a reliable cargo tank testing service that can keep your tank compliant with Department of Transportation (DoT) regulations? White Tank & Truck Repair has you covered. Give our team of experts a call today.

The Benefits of White Tank’s Inspection Process

By adhering to stringent regulations and employing advanced techniques, we have become a trusted partner for maintaining the highest standards.

Compliance

Our DoT Cargo Tank Testing inspection process ensures compliance with all regulatory standards. Conducting thorough inspections and following strict protocols, we help businesses avoid potential fines, penalties, and operational interruptions.

Safety

Safety is our top priority when transporting hazardous materials. Our DoT Cargo Tank Testing inspection process identifies potential vulnerabilities or defects that could have resulted in accidents, leaks, or spills, harming the environment and individuals involved.

Testing Capabilities

We utilize state-of-the-art testing equipment and techniques to thoroughly assess the condition of cargo tanks. Our process covers various essential aspects, including structural integrity, leakage detection, pressure testing, internal lining, and more. This comprehensive approach provides a detailed evaluation of the cargo tank’s condition, offering insights into areas that require maintenance or repair.

Timely Maintenance and Repair

Early detection of issues through our inspection process allows for timely maintenance and repair. By addressing concerns promptly, we help businesses avoid costly and lengthy fixes in the future. Quick maintenance ensures that cargo tanks remain in optimal condition, minimizing the risk of unforeseen breakdowns or failures during transportation, saving both time and money.

White Tank & Truck Repair: Your Source for DoT Cargo Tank Testing and Inspections

With White Tank & Truck Repair as your trusted partner, you can rest assured that your cargo tanks will meet the necessary inspection and certification requirements. Our comprehensive range of services, including yearly inspections and five-year certification tests, keeps you in line with PHMSA regulations.

By choosing us, you prioritize safety, compliance, and integrity. Contact White Tank & Truck Repair today and experience our commitment to excellence in cargo tank inspection services.