Tank Truck Welding Safety: Best Practices to Follow

Regular tank truck maintenance and repairs are always a constant in the trucking industry, and one factor that goes along with this is welding. Safety in welding is no joke, and staying updated on best practices is essential. Adequate knowledge and implementation of safety measures can ensure the well-being of welders and even prevent accidents.

Read on to learn the basics of truck welding safety and get a detailed analysis of ensuring welding safety on different types of trucks and welding processes.

The Basics of Tank Truck Welding Safety: What You Need To Know

Tank truck welding safety starts with understanding the common hazards associated with the task and how to mitigate them. Challenges range from the risk of electric shock to burns and eye damage. There are also typical calibration requirements and recommended standards from the Advanced Career Institute to consider.

Key Components of Tank Truck Welding Safety

The key components include personal protective equipment. Welders need heat-resistant gloves, eye protection like safety glasses or goggles, and ear protection. It’s also crucial to adopt preventative maintenance of the welding equipment and follow the position statement on safe welding.

Responsibilities of a Safe Welder

A safe welder should always run a repair system scanning before starting any welding fuel tank job. The welder is also responsible for adhering to safety protocols, including managing the electric vehicle to ensure the vehicle’s protection. Preventative maintenance is crucial to ensure the truck runs safely.

OSHA Guidelines for Tank Truck Welding Safety

The OSHA guidelines for truck welding safety focus on protecting employees from welding hazards. They recommend wearing proper attire and using ear muffs and stress the importance of rock sliders as a protective measure in welding areas. These guidelines also emphasize the importance of having a quality repair process.

Importance of Training and Education for Welders

Training is vital for welders to understand the great designs possible with techniques like MIG brazing. Multiple resources can offer this training, including the Advanced Career Institute. An educated welder is more likely to perform quality repairs and meet calibration requirements.

Explore White Tank & Truck Repair’s welding services to see how certified professionals handle the job.

7 Best Practices for Welding on Tank Trucks

When it comes to tank truck welding services, there are several safety measures to be aware of, like maintaining safe equipment and ensuring the working environment is conducive.

- Setting up a Safe Welding Environment: The first step to safe welding is setting up a secure work area. This includes checking the tank truck wash system, inspecting the workspace for any risk of electric shock, and prepping the MIG welder for the work ahead.

- Tanker Truck Welding Safety Techniques: These techniques include maintaining the safety of the truck repair, ensuring that the welding work is completed correctly, and confirming that the fuel tank welding follows the position statement from the organization on safe welding.

- Safety Concerns Specific to Different Welding Processes: Different welding processes have specific concerns. For example, MIG welding requires shielding gas, which can displace oxygen and cause asphyxiation if not correctly handled, while welding fuel tanks require enough ventilation to prevent the build-up of harmful gases.

- Maintaining Safe Truck Welding Tools and Equipment: Safe truck welding equipment requires regular checks and adjustments. This includes testing the smooth functioning of the advanced driver assistance systems, checking the white tank regularly, and timely preventative maintenance.

- Safety Guidelines for Gas Welding: Gas welding necessitates understanding the combustion characteristics of gases used, and welders must ensure a suitable ventilation system to keep the gas levels in check.

- Protective Measures for Resistance Welding: Resistance welding requires welders to wear heat-resistant clothing, use rock slider restraints, and ensure their ear muffs for protection from noise.

- Maintain Ventilation: Proper ventilation is essential to prevent the build-up of harmful gases and fumes. For welding fuel tanks, checking and maintaining oxygen and gas levels inside tanks is critical for safety.

How to Avoid the Need for Tank Truck Welding Services

The first step to avoiding tank welding repairs is driving safely and being mindful of your surroundings when parking or pulling up to fill stations. But there are other steps to keep your truck bed, tank, and other equipment in good condition.

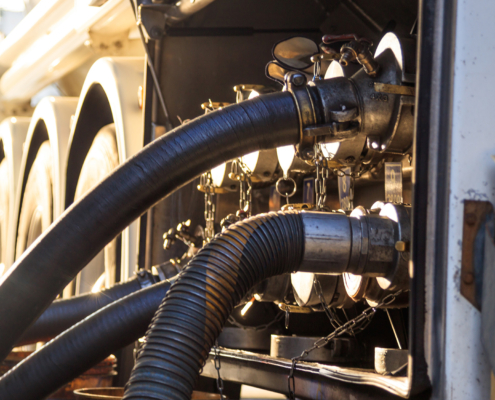

Tank Truck Wash Systems

Tank cleaning is essential in keeping drivers, service workers, and cargo safe. Cleaning and sanitizing tanks prevent cross-contamination of food, chemicals, and other goods transported. Additionally, a thorough tank truck system reduces the chances of welding equipment sparking an explosion brought on by trapped vapors or gas remnants.

Tank Truck Welding Preventative Maintenance

Truck welding is typically used to correct significant tank issues. Things like collisions cause the immediate need for welding fuel tanks, but neglect often leads to repair needs. If you’re not taking your truck in for routine preventative maintenance and inspections, you’re vulnerable to prolonged downtime, costly replacements, and safety concerns.

Preventative maintenance allows experts to examine your truck and tank for minor issues that experts can quickly fix before requiring substantial repairs like tank welding. Don’t let a $20 part replacement lead to thousands of dollars worth of truck welding work because you didn’t make time for a maintenance visit.

Guarantee Truck Welding Safety With White Tank & Truck Repair

Provide the highest level of safety for your tank truck welding needs with White Tank & Truck Repair. Our experienced technicians are trained in the latest welding techniques and safety protocols, ensuring your truck repairs are performed to the highest standards. We use state-of-the-art equipment and follow rigorous safety measures to prevent accidents and ensure durable, reliable welds. Trust our team for all your truck welding requirements, where safety and quality are our top priorities. Secure your truck’s longevity and performance with White Tank today.