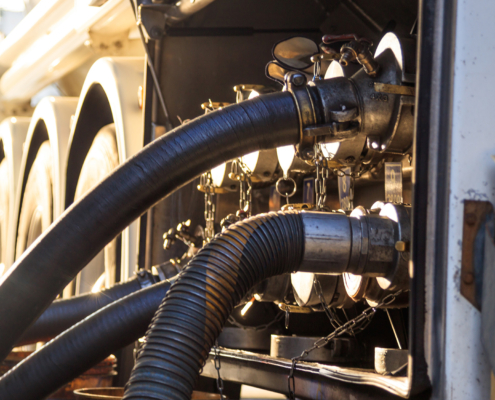

Overfill prevention devices are designed to quickly and efficiently shut off flows when spillage is detected in storage tanks. These monitoring safety systems are ideal for both top-loading and bottom-loading tank trucks equipped with sensors.

While a bottom tank device, known as a retain sensor, warns truckers that their tank is getting low and needs fuel, the top tank device, known as an overfill sensor, alerts them to stop filling to prevent overflow. Both sensors work collaboratively to ensure systems operate smoothly and safely.