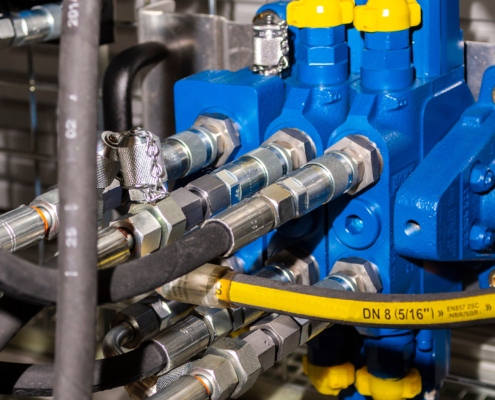

The installation of wet kits requires navigating hydraulic pump arrangements and valving systems, each designed to precisely control fluid flow. With numerous components and intricate mechanisms at play, wet kit installations demand an in-depth understanding of hydraulic systems. Entrusting the installation process to experienced providers ensures accuracy and reliability.

For those seeking insights into the installation process, we’ve compiled a comprehensive list of tips:

- Transmission Oil Check: Before starting the installation process, verify that the transmission oil levels are adequate for proper lubrication and hydraulic system performance.

- Ball Valve Safety Measure: Open the tank’s ball valve and securely tie it to prevent accidental closure during installation, minimizing the risk of fluid leaks or system damage.

- Pump Priming: Make sure the hydraulic pump is flooded with oil before installation to facilitate smooth operation and prevent air pockets within the system.

- Pump Rotation Correction: Verify the rotation of the hydraulic pump so it aligns with the desired direction of fluid flow, correcting any discrepancies as needed.

- Fitting Inspection: Thoroughly inspect each cap and plug in the system so all fittings are tightly secured to prevent leaks and maintain system integrity.

- Three-Line System Considerations: If you’re installing a three-line system, make sure the sleeve is correctly installed in the suction port to optimize hydraulic fluid flow and prevent air ingress.

- Hose Connection: Inspect hose connections to confirm they are leak-free and tightly secured, minimizing the risk of fluid loss and system malfunction.

- Optimal Fluid Level: Check that the hydraulic system is filled to approximately two-thirds of its capacity, allowing room for oil expansion due to heat and preventing overfilling.

- Bolt Torquing and Oil Management: Correctly torque all mounting bolts to secure components and remove any excess oil from the system for optimal fluid levels.

- Secure Hose Fastening: Use sturdy zip ties or brackets to secure hoses to the frame, preventing damage or interference during operation.

- Filter System Maintenance: For three-line systems, ensure proper filter flow, mount security, and leak-free filter connections to optimize filtration efficiency and prevent contamination.

- Airlines Routing: Route cab control airlines away from hot or sharp components to prevent damage and ensure safe operation.

- Leak Inspection: After completing the installation, start the wet line kit and inspect the system for any leaks or abnormalities, addressing them promptly for optimal performance.